Search term must have more than 2 characters.

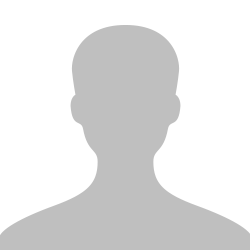

- Quick change clamping system Otevřít podmenu: Modular clamping system ZEPo-v

- CNC Automation & Accessories

Otevřít podmenu: Robot point

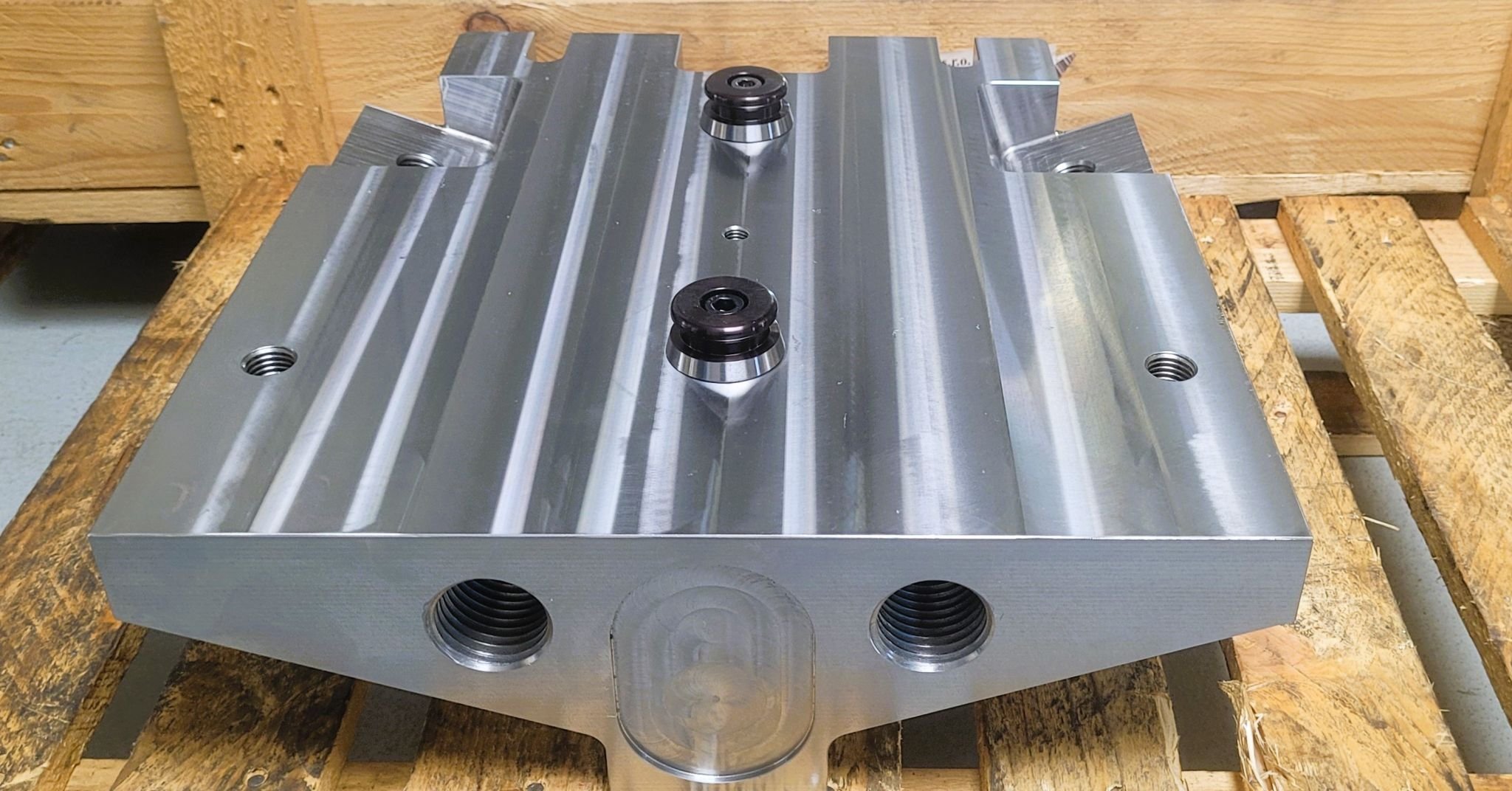

- Pneumatic Clamping Bases

- Robot point

- Quick change robot clutch

- Automatic pallet stack Otevřít podmenu: Automatic pallet stack

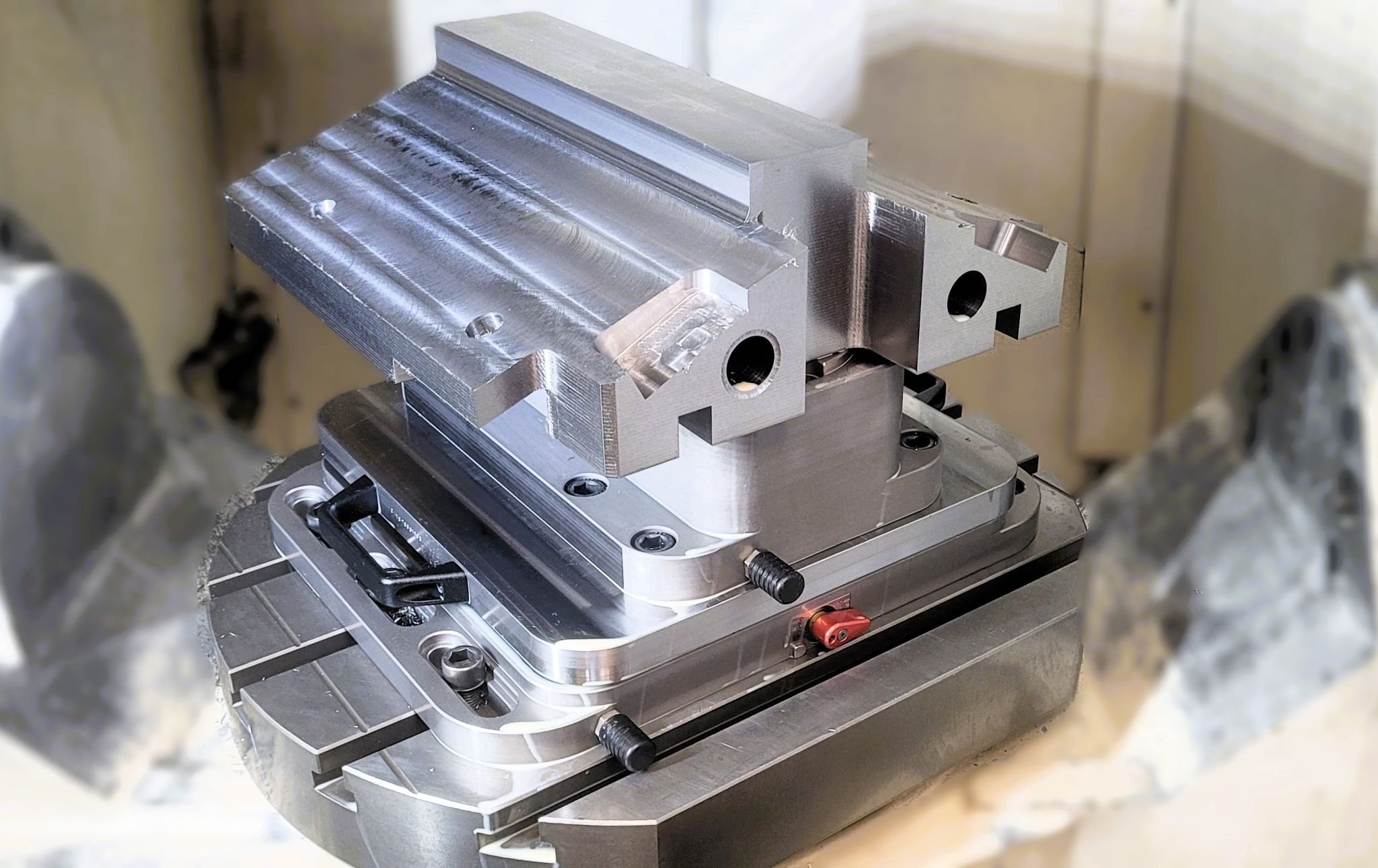

- Interchangeable Pallets for Automation Otevřít podmenu: Interchangeable Pallets for Automation

- Supply compensator

- Spare parts

- Production SW Otevřít podmenu: Production SW

- Custom manufacture

- About us Otevřít podmenu: About us