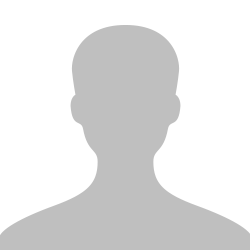

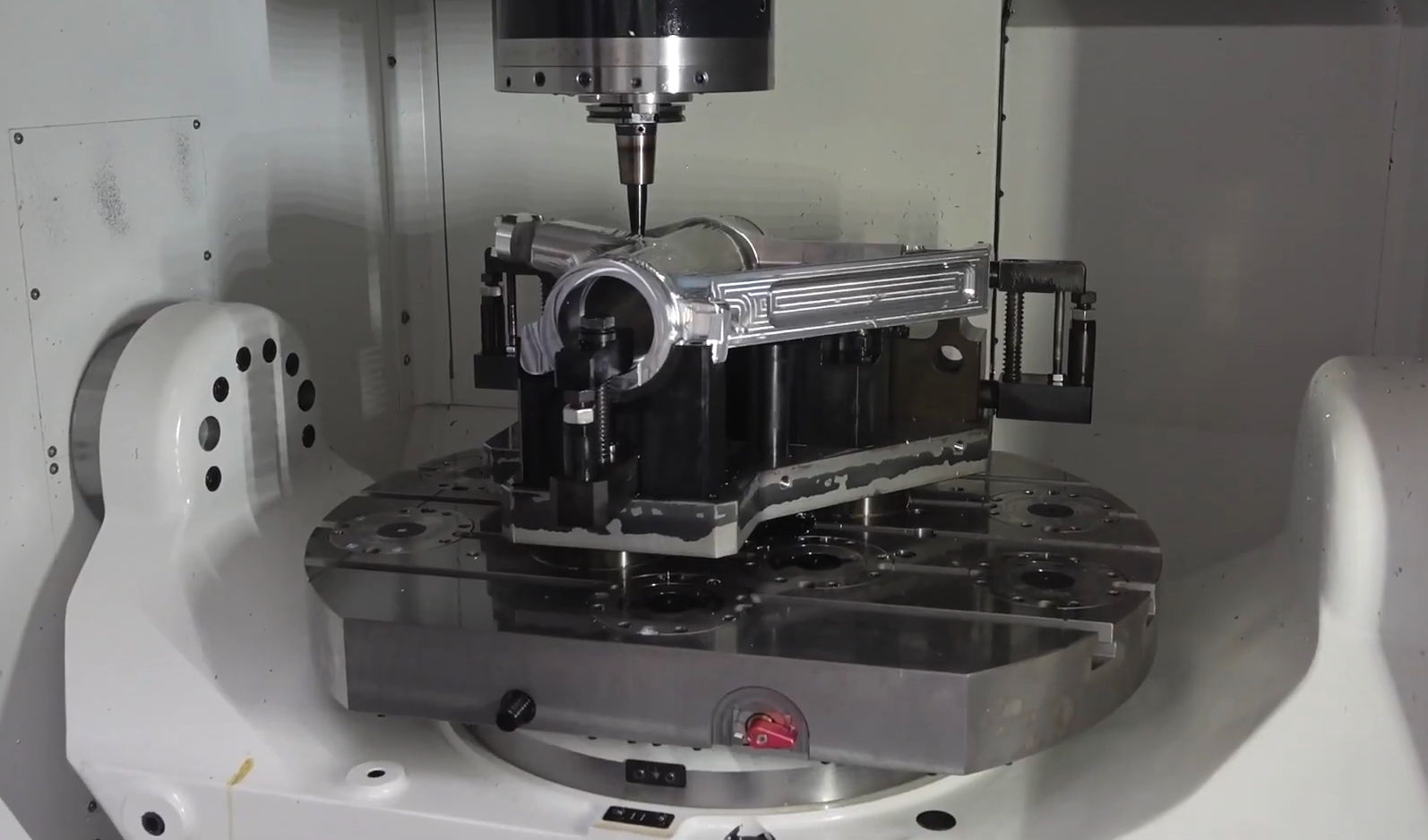

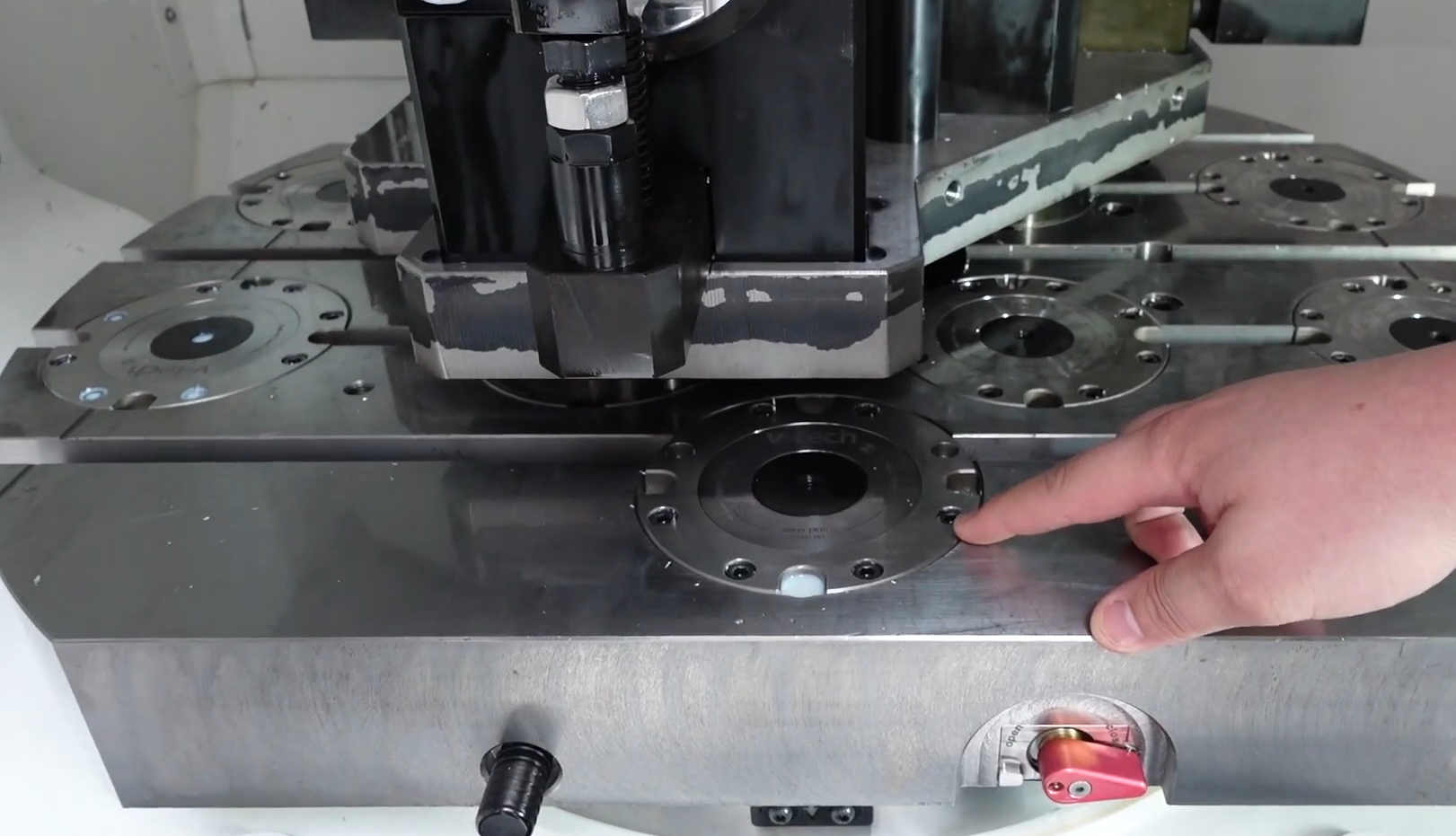

In the machining of complex parts, every hundredth of a millimeter counts, and the clamping method plays a key role. At v‑tech s.r.o., we have designed and delivered an embedded zero-point system directly integrated into the table of a Mazak Variaxis i800 NEO. The result is maximally precise and fast positioning of workpieces in small-batch production of aerospace components.

We implemented this custom solution for CHARVÁT AXL, a.s., where the system brings clear advantages. These include consistent repeatability, minimal part changeover time, and reliability even during multi-sided machining. In this particular application, the part is machined using five-axis simultaneous machining in 90% of the operations.

📽 Watch a short video from the production process